Author: cblankley

A Cut on the Bias as Project Journal

After a period of rest for this blog, I’ve decided to revive it as a sort of travel journal, newsletter, and memory album for reflections over the coming months of a large IT project involving significant transformation at two Scandinavian clothing brands.

IT projects are business projects, and vice versa. This has never been truer, and everyone in each Company will be feeling it through this IT Independence Program – technically two projects, separating each brand out of it’s previous “home” of shared applications.

It’s not everybody in this world who gets an opportunity to follow a journey like this, and from inside the whirlwind it can be difficult to take a step back and reflect on the lessons as we learn them. For those of you on this journey with me, please don’t hesitate to share your thoughts, funny anecdotes, suggestions for future topics or just let me know how you’re doing.

It’s the intention of this blog, for now, to function as a kind of informal project journal and newsletter, to keep perspective on the bigger picture and help each other to keep learning and have some fun along the way.

I wrote the above in August 2022, and concluded with these words of wisdom: try to get up and WALK! We spent so much of the spring glued to Teams screens for hours on end. For the first couple of weeks back at work after summer, I’ve gotten in the habit of taking every possible one-on-one meeting on my feet. Now to see if we can keep the habit when the weather turns less glorious…

RFID Rundown

Digitalisation is a big focus area, say we and pretty much everyone else these days. Which makes plenty of sense, not just from a techie perspective. Particularly in the Retail space, Ecommerce is the one channel that is still showing double-digit growth. But there’s more to Digital than webshops, and I’ll delve deeper by devoting the occasional column to other relevant Digital dilemmas.

I keep hearing about RFID? Are there real implications for my brand? RFID is one of those relatively unsexy topics that generally only get my Logistics friends up out of their chairs. Short for Radio Frequency Identification, what it means in the apparel world, is a small chip in the garment’s hangtag or another label, which enables a unique ID for that item – not the SKU, not the style/colour/fit/size (of which there can be hundreds of units), but that single, individual unit.

What would we get out of that? Assuming that you had the production facility to make the labels and affix them to the garments, and invested in the tools, you could:

- Scan your inbound goods receipts a whole pallet at a time, more or less eliminating the need for pre-advice to the Warehouse Management System and ensuring full stock counts at inbound (this is where Logistics lights up)

- Perform stock counts in the shops, using a “wand” that picks up the radio frequencies (this is where Retail lights up)

- Some business are experimenting with tracking the movements of the garment around the shop. How often did it get picked up? How often did it go into the fitting room?

Sounds great! I’ll take two… Well, it’s not quite that simple. Some considerations, just to get started:

- There are many kinds of RFID chips, and the technology has been improving yearly. Nevertheless, the accuracy of pallet-scanners on boxes as tightly packed as some of ours, is so far not 100% reliable (based on references during WMS project investigations)

- Did someone say GDPR? There has been controversy in certain countries, about business’ use of tracking movements of the garments after consumer purchase. An important consideration therefore, is de-activation of the chip when it leaves the shop premises.

- Not to mention, that you can only harvest these benefits, once you have invested in the relevant hardware and software to manage them.

What else is happening in the world of unique product IDs?

- NFC (Near Field Communication) tags can be made super-thin and discreet – but can only be read at close range, and therefore don’t enable the “inventory by wand” solutions.

- Several players like Verisium are playing with using Blockchain to register tagged raw materials such as organic cotton,

Some say RFID is already dying, others say it’s in it’s infancy. Blockchain technology is bringing new opportunities in the form of massive data processing power, to handle the huge volume of potentially trackable movements and transactions per unit.

Inspirazzione: A Whirlwind Tour of the latest in Product Innovation

I had the privilege of participating in the PI Apparel conference in Milan this October: my yearly dose of external inspiration, conscience-soothing, brain-busting and network expansion in one crazy intensive package.

Here are some of the highlights I’ve managed to digest so far:

HOPE FOR THE SOCIAL CONSCIENCE

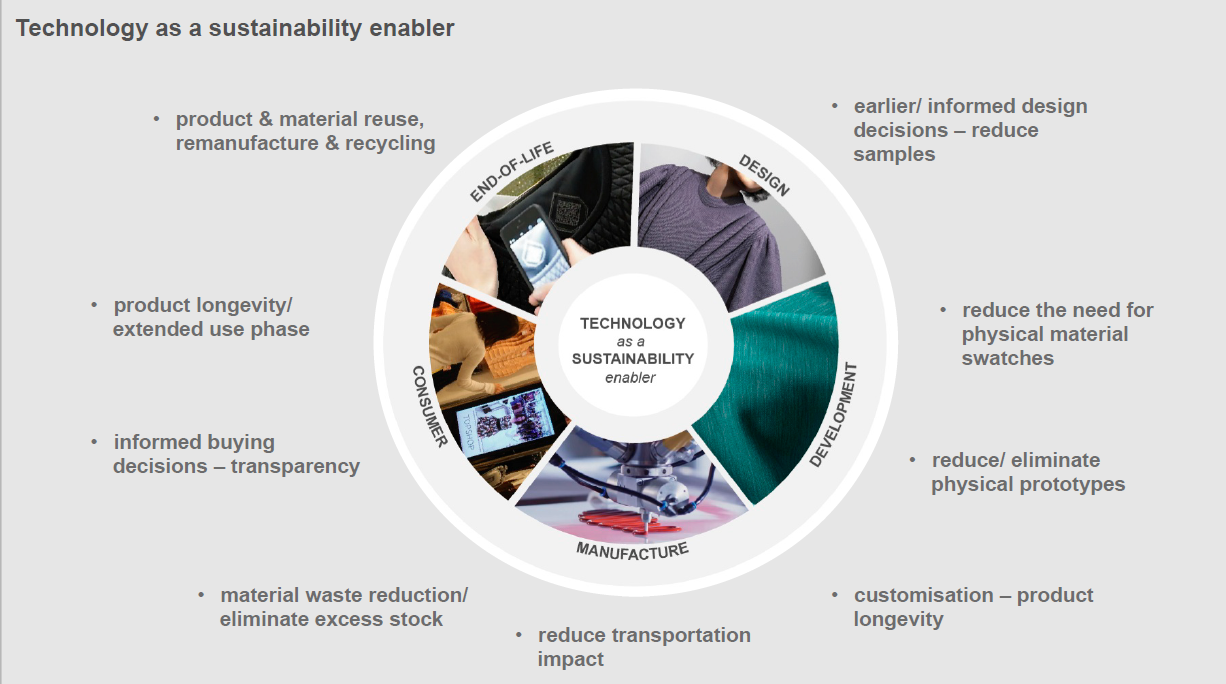

No matter how much fun I have every day in this business, I do worry about what our industry does to the planet and it’s less fortunate occupants. There were plenty of people talking about how Digital will reduce the number of samples being produced, flown around the globe, and wasted (more on that later). I got really inspired talking to people like Pim from Fashion for Good, following a panel on Sustainability hosted by Anna Prahl, and listening to Sarah Krasley tell the story of Shimmy Upskill, a program designed to equip unskilled factory workers in places like Bangladesh, for the automation wave that is on it’s way.

In as little as 4 hours, women who had never before used a computer, learnt the basics of preparing markers for an automated fabric cutting process. With the vision of being “as addictive as Candy Crush, as approachable as an older sister, and bringing value to brands”, Shimmy is designed as a voice-activated video game in IBM Watson, configured to “speak” in Bangla (thanks to the wives and families of New York taxi drivers!), and tested so far in collaboration with Tommy Hilfiger on two product groups.

I was gripped by the idea of turning the very tools which are predicted to put these so-far unskilled workers out of a job, into a means for giving them skills to bring value to future production methods. It does my fashion-business heart good to know that there are people like Sarah, Anna and Pim out there, and thankfully many more.

DIGITAL, DIGITAL, DIGITAL

Yes, yes, it’s not news anymore: Digital is coming, we need to foster the skills, invest in the tools, reduce our physical samples, we have got the memo. What this year’s conference told me, was that it doesn’t all have to happen at once. “3D is hard!” said one of the keynotes, and he wasn’t just talking about the tools. But I came here to be inspired, and I got just what I ordered, not least from The Fabricant (positioning themselves as the world’s first digital-only brand – no physical clothes!), from Human Solutions (slightly more relateable to our world, showing where in the value chain digital can bring the fastest value), and from our old friends Hugo Boss, who are now 5 years in to their digital journey, and shared many insights into the challenges along the way.

From Andreas Seidl, Human Solutions: 3D and Beyond – Creating a Whole New Fashion World

Everybody here is talking about 3D, avatars for sizing, digial design, etc. But this presentation took it beyond the gadgets and out to strategy and practicalities. Seidl showed a very recognisable product development slide (title: Time is the Pain) and related the various elements to where digital initiatives can reduce months to minutes.

FRIENDS IN THE BIZ

One really nice aspect of the event, was the openness and willingness to share experiences even with competitors – within reason, but in general there’s an atmosphere of sharing wisdom for the greater good of the industry.

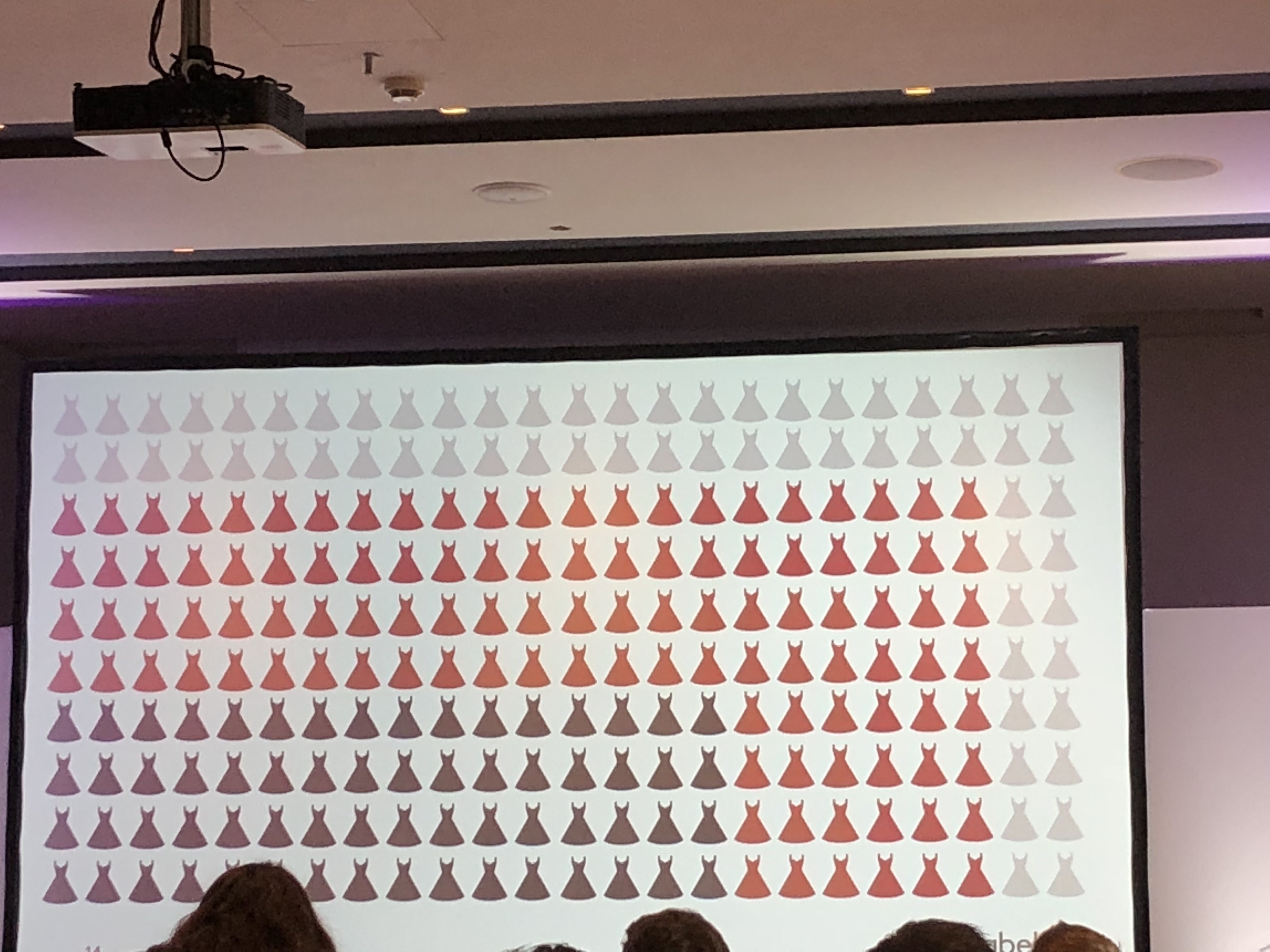

So when the Zalando private label “zLabels” directors drew that picture we all know so well, of minimum purchase quantity vs. actual desired qty vs. actual sold qty, and how many actually were desired by the customer, and from that talked about the importance of supplier relationships to enable smaller purchase minimums… well duh, we all thought. But of course Zalando has data, tons of data, not only about sales of their own brands but all of ours, and all those numbers go into their decisions: build transparent long-term relationship with suppliers, use data to achieve shared understanding and make best decisions, avoid waste not only in resources but also time and money.

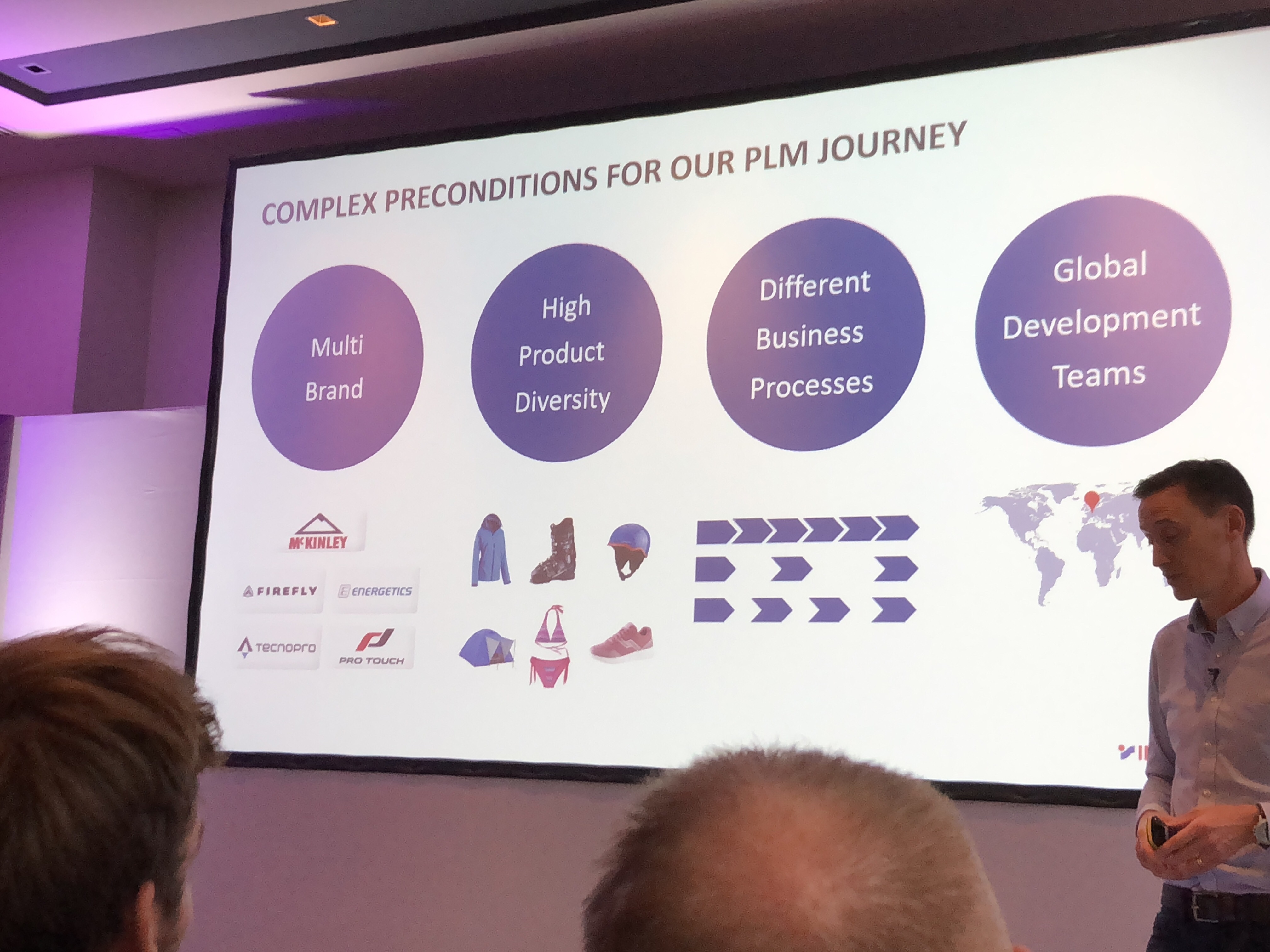

Intersport was there too, now well into a PLM implementation for their own private label brands (about 18% of their business). They sought business value by harmonising their data structure and business processes, concentrating their ranges, and yes, reducing their selling samples. Their journey, too, continues… but so far they have got their suppliers downloading their tech packs straight from the tool, and much of the PIM data is now automatically populated. I nearly asked the guy why if they’re so harmonised, they can’t receive same EDI format to their stores in different countries… but that would be a different story.

Pentland Brands, who have Speedo and Hunter among many others, are also mid-PLM implementation; their story was about “Hundreds of Colours, Multiple Brands and One PLM”. They use a tool called Coloro to synchronise and ensure a single version of every colour used.

And finally, Hugo Boss didn’t disappoint; their Team Leader 3D Virtualisation described their journey since 2013, through development of Forms, Styles, virtual protos, virtual styles, and eventually sales material – delaying the need for physical production longer and longer. It was a healthy reminder that digital design journeys are not that different from physical ones – constantly being tuned and revisited!

BLOCKCHAIN – in APPAREL?

Described as “an endless spreadsheet that everyone can write to but no one can delete from”, and “a solution in search of a problem” – this workshop was about some of the possible applications of blockchain in the apparel industry:

- Anti-counterfeiting

- Transparency / compliance / traceability

- Sustainability

- Trade finance

- Shipping / Logistics

- Customer engagement / marketing

- IoT connected product interaction

In particular, the transparency of supply chain was a source of various discussions: ways to ensure that the certified organic cotton you believe you are buying, is indeed sourced as claimed – but it doesn’t necessarily solve the fundamental challenge, of guaranteeing that the source of the information entered into the blockchain is ethical and correct.

The moderator told us about Loomia’s circuitry-embedded fabrics, which were planned for a customer engagement project with LL Bean; not only would they use blockchain to trace the provenance of the materials, but also, pending an opt-in from the consumer, report back on temperatures experienced, number of washes, and reward the consumer for sharing the data.

There are concerns about data scalability, power consumption of server farms, governing authorities. It will be interesting to see the state of the technology already this time next year.

ONE MORE BRAIN-BUSTER

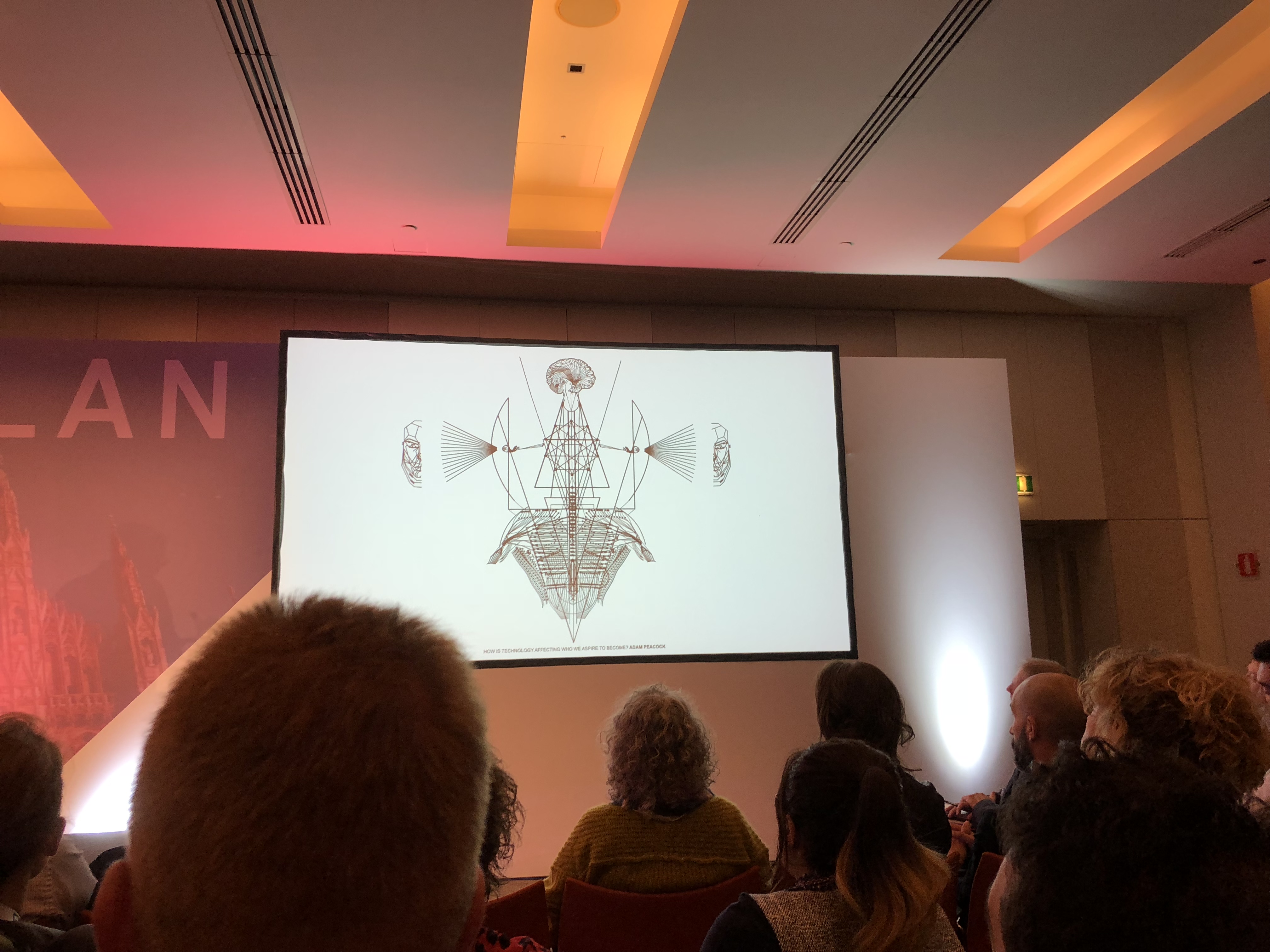

Adam Peacock, designer, artist, experimenter, has been up to some wild stuff. Taking the current interest in genetics and AI to the next level, he created an art installation called the Genetics Gym, applying various (realistic or not) genetic selection options from a menu, to 5 images of different people – then extending those perceptions using computational design. Fascinating, challenging sometimes beautiful, and a little bit scary – asking more questions than it answers, I came away reminding myself to keep an eye on that tendency to wish ourselves different than we are.

It would be natural to feel intimidated in the presence of so much innovation, disruption, and downright digitalness, and to wonder how brands like ours ever will catch up. I’m not panicking though – quite the reverse, I feel hope for our industry and our brands, and while it’s clear we all have work to do, we are far from alone out there. I think the key is to make sure we keep a part of our strategy – in IT and in the brands in general – allocated to self-development, to nurturing skills, and finding great collaborative partners to share the journey.

BIBLIOGRAPHY

Want to know more? Here are links to above and others of potential interest:

On Digital

Coloro: Colour standardisation: www.coloro.com

On Sustainability

On Blockchain

Midsummer Reflections

Thanks for joining me!

Good company in a journey makes the way seem shorter. — Izaak Walton

WEEK 25-26, 2018 – by Cindy

We´re in a period of transition and reflection. Wrapping up the last details on big projects like New Legal Structure and Flat Sorter, gearing down (up?) for summer holiday season, and getting emotional about our last few days of shared ownership with Peak Performance.

The kids grow up so fast, seems like just yesterday we were finding our feet together as InWear and Carli Gry joined forces to become IC Companys!

There´s no doubt about it, the coming year of transition handover from IC Group systems to Peak´s future setup is going to be nothing short of fascinating, educational, probably exhausting, and hopefully we´ll all come out of it even stronger. But more on that another day.

Three things that have inspired me this week:

1. Collaboration at By Malene Birger, where various teams together worked through some of the challenges introduced by the transparencies and automations of the new Samples process. BMB planned the workshop, and drove the agenda, and invited us along to help keep the discussion on track and add perspective where needed. Thanks to Anette Kroløkke and the rest of the team for checking in!

2. Read: Hit Refresh, by Satya Nadella, Microsoft CEO – I´m not a Microsoft fangirl, but this book struck a note with me. I found lots of parallels with their transformation towards a more empathetic, empowering, partnership-focused culture and mindset. Together with Anders, I decided to “hit refresh” on our IT Governance format, simplifying our overviews and tuning the meetings to fit each brand’s pace and culture; the re-launch is already in progress.

3. My team of superheroes – talk about bias, you guys inspire me every day! But in this OKR season, we dig a little deeper and give ourselves permission to step back and consider our role in the big IC world and beyond. I´ll try not to be this gushy on every blog post – but humour me on this inaugural one, as we put a bow on the finance year 17/18 and prepare to throw ourselves into the new one… thank you Bente, Daniel, Inma, Krzysztof, Lotte, Ove, and Vanessa, for taking such good care of our Brands and each other.